Top Bakery Product Machinery Innovations for Modern Baking Success?

In the rapidly evolving world of baking, innovations in bakery product machinery play a crucial role. Experts in the field, like John Baker, a leading machinery consultant, emphasize the impact of technology. He states, "The right machinery can transform traditional baking methods into something extraordinary." This highlights the need for modern advancements.

Today's bakeries face numerous challenges. Balancing speed and quality is essential. Consumers demand freshness and variety. With an array of machinery options, choosing the right tools can be daunting. Many bakers struggle to keep pace with trends and innovations. This creates a gap between production capabilities and market expectations.

As the industry advances, ongoing training and adaptation are vital. Embracing new technologies can enhance efficiency and creativity. However, not all innovations yield immediate results. Some require reflection and adjustment. The quest for modern baking success intertwines with our understanding of efficient bakery product machinery. It is in this blend that true mastery of baking lies.

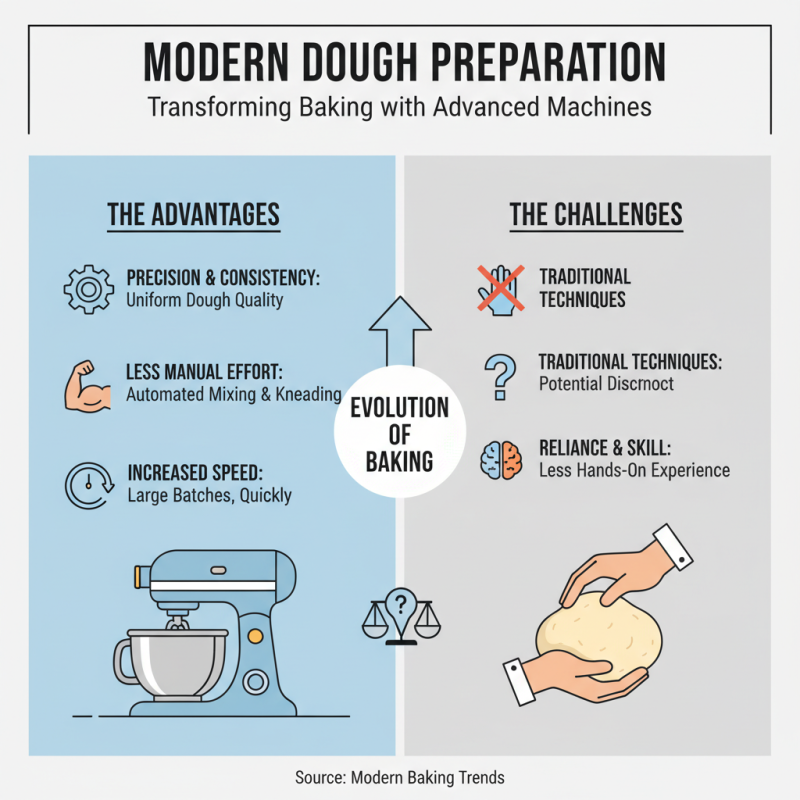

Revolutionizing Dough Preparation: Advanced Mixers and Kneaders

In modern baking, advanced mixers and kneaders are transforming dough preparation. These machines allow bakers to achieve the perfect texture with less manual effort. The precision of these tools can reduce inconsistencies in dough quality. Many bakers find themselves amazed by the speed at which they can mix large batches. However, reliance on machines sometimes leads to a disconnect with traditional techniques.

While these innovations bring efficiency, they present a learning curve. New users might struggle to understand settings and functions. Adjusting to a machine's specifics can take time and practice. Some bakers miss the tactile feeling of kneading by hand. The art of baking can sometimes feel mechanized. This transformation begs the question: Are we losing the essence of baking?

Despite these machines, flour and water still require careful measurement. The precision helps with consistency, but there’s joy in the imperfections. Each batch can tell a different story based on small changes in technique or ingredients. It’s essential for bakers to find a balance between innovation and tradition. Exploring both paths might lead to the best results.

Innovative Baking Ovens: Ensuring Efficiency and Uniformity in Baking

Innovative baking ovens are transforming the bakery industry. They ensure both efficiency and uniformity in creating delicious products. With advancements in technology, modern ovens now provide precise temperature control. According to a recent industry report, bakeries can increase production by up to 40% with these advanced systems.

Efficient heating methods, such as convection and radiant heat, contribute to consistent baking results. These ovens reduce the risk of unevenly baked goods. A study shows that uniform heat distribution can enhance product quality, leading to higher customer satisfaction. However, it is essential to regularly maintain this equipment for optimal performance.

Tip: Look for ovens with programmable controls. This feature helps bakers manage baking times effectively. Moreover, using steam injection can improve crust and texture.

Another consideration is energy consumption. While these ovens are efficient, they can also be energy-intensive. Evaluating energy costs is crucial. Balancing between efficiency and sustainability is a challenge many bakeries face today. This gap often leads to higher operational costs. Careful planning can mitigate these issues while maximizing the benefits of advanced baking technology.

High-Tech Proofing Solutions: Optimizing Fermentation Processes

Modern baking relies heavily on high-tech proofing solutions that optimize fermentation processes. These innovations help bakers maintain precise temperature and humidity levels. A consistent environment is crucial for dough to rise perfectly.Advanced sensors monitor conditions in real-time, ensuring the best results.

However, not all high-tech solutions are flawless. Issues can arise with equipment accuracy. Sometimes, fluctuations in temperature can lead to unexpected results. Bakers may find themselves adjusting recipes constantly. This trial-and-error approach can be frustrating, yet it teaches valuable lessons about dough behavior.

Integrating technology into a bakery must be done thoughtfully. Over-reliance on machines may overshadow the artistry of baking. Bakers should balance innovation with traditional methods. Documenting outcomes is essential to refine the process continuously. With careful observation and adaptation, modern bakers can truly harness the power of technology.

Automated Packaging Systems: Streamlining Production and Distribution

In the rapidly evolving bakery sector, automated packaging systems have become vital. The global bakery packaging market was valued at approximately $16 billion in 2022. This growth underscores the importance of efficiency and consistency in production. Automated packaging significantly reduces labor costs and minimizes human error. Efficient machines can boost output by up to 30%, enhancing profit margins for bakeries.

However, relying solely on automation has its drawbacks. Many bakeries face challenges in integrating new systems. Training staff on advanced machinery requires substantial time and financial resources. If not managed well, this can disrupt production rather than enhance it. Additionally, quality control remains a concern. Some automated systems may overlook slight imperfections that a trained eye would catch.

Striking a balance between automation and human insight is essential. Though automated systems can streamline production and distribution, they must complement skilled workers, not replace them. The innovation in packaging must align with a bakery’s unique offerings. Focusing solely on efficiency may lead to generic products. Baking is as much about craftsmanship as it is about speed. Finding this balance is a constant struggle for many in the industry.

Innovations in Bakery Product Machinery

Sustainability in Bakery Machinery: Eco-Friendly Innovations for Modern Operations

Sustainability is becoming crucial in bakery operations. Eco-friendly machinery can help reduce waste and energy consumption. Many bakeries are now shifting towards equipment made from recycled materials. This not only lowers their carbon footprint but also attracts environmentally conscious consumers.

Some innovations include energy-efficient ovens and mixers that reduce electricity use. These machines are designed to optimize baking time and reduce emissions. However, many bakeries still face challenges in fully adopting these technologies. The initial investment can be high, and not all machines are easy to integrate.

Moreover, the quest for sustainability does not end with machinery. Training staff to operate these machines effectively is essential. Without proper knowledge, even the best equipment may underperform. Continuous reflection on practices is necessary to ensure the right balance between efficiency and environmental impact.

Related Posts

-

Top 10 Essential Food Machinery Equipment for Your Business Success

-

Why Choosing the Right Creamery Equipment is Essential for Your Dairy Business

-

How to Choose the Best Fruit Machinery for Your Business Needs

-

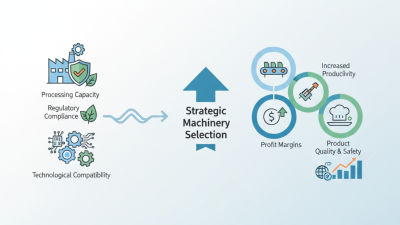

How to Choose the Right Food Industry Machinery for Your Business Needs

-

What is Creamery Equipment and Its Importance in Ice Cream Production

-

10 Essential Tips for Choosing the Right Dairy Machinery for Your Farm

Sell your machinery

Call us now on

+44 (0)1373 831 373

Sign up to our newsletter

Monkspool House,

The Stable,

Woolverton, Somerset.

BA2 7QT

United Kingdom