10 Best Cheese Equipment You Need for Perfect Cheese Making at Home

When it comes to the delightful world of cheese making, having the right cheese equipment is essential for achieving that perfect flavor and texture in your homemade creations. Whether you are a beginner looking to embark on your cheese-making journey or an experienced artisan eager to expand your repertoire, the proper tools can significantly influence the quality of your cheese. This guide introduces you to the ten best cheese equipment pieces you need to elevate your craft at home.

In this exploration, we will delve into the fundamental tools every cheese maker should consider, from essential items that facilitate the curdling process to equipment that aids in aging and storage. By recognizing the importance of each piece of cheese equipment, you can streamline your processes and enhance your overall cheesemaking experience. As you navigate through the world of cheese production, having this guide at your fingertips will ensure you are well-prepared to create delicious, artisanal cheese right in your kitchen.

Essential Cheese Equipment for Successful Home Cheese Making

Home cheese making has gained popularity among culinary enthusiasts, with a significant increase in interest over the last decade. According to the Specialty Food Association, the cheese-making market has seen a steady growth of 10% annually, driven by a surge in demand for artisan and homemade products. To achieve success in this rewarding hobby, having the right equipment is essential.

Key items for a smooth cheese-making experience include a high-quality thermometer, which is crucial for accurately monitoring milk temperatures during curd formation. Studies indicate that precise temperature control can significantly affect the texture and flavor profiles of homemade cheese. Additionally, a reliable cheese mold and press are necessary to shape and compact the curds, ensuring optimal moisture content throughout the aging process. The importance of maintaining proper acidity and moisture levels is further emphasized by research from the Dairy Science Journal, which highlights that these factors directly influence the quality and safety of the final product.

Investing in a good cheese mat is also recommended, as it allows for proper drainage and airflow during the curing phase. Alongside a stainless-steel pot for heating milk and a long knife for cutting curds, these pieces of equipment lay the foundation for a successful cheese-making endeavor. Adopting these essential tools not only enhances the quality of the cheese but also elevates the overall experience, making homemade cheese making a gratifying pursuit for enthusiasts.

Understanding the Importance of Temperature Control in Cheese Production

Temperature control is a critical aspect of cheese production that directly influences flavor, texture, and the overall quality of the final product. Each type of cheese requires specific temperature ranges during various stages of the process, from curdling the milk to aging the cheese. For instance, heating milk to the right temperature ensures that lactic bacteria can flourish during fermentation, leading to proper acidity development. Conversely, excessive heat can kill off these beneficial microbes, resulting in a subpar cheese with undesirable characteristics.

Additionally, maintaining a stable temperature during the aging process is essential for developing the cheese's flavor profile. Most cheeses need to be kept at cool, consistent temperatures to allow the enzymes and bacteria to work their magic over time. Fluctuations in temperature can cause the cheese to dry out or develop unwanted textures. Thus, investing in reliable temperature monitoring equipment is vital for any home cheesemaker aiming to create exceptional cheese.

Understanding these temperature dynamics not only enhances the cheese-making journey but ultimately results in a more rewarding and delectable outcome.

Key Tools for Measuring pH Levels in Cheese Making

When it comes to cheese making at home, measuring pH levels is critical for achieving the desired taste and texture. The pH level in cheese affects the curd formation, moisture retention, and even the overall flavor profile. For instance, studies show that the ideal pH range for most cheese types falls between 5.0 to 5.5 during curd formation. Accurate measurement of pH is essential in this process, as even small deviations can lead to unwanted changes in the final product.

To effectively monitor pH levels, cheese makers should invest in reliable pH meters or strips. According to the Dairy Research Institute, pH meters provide a more accurate measurement compared to strips, which is vital for precise control over the cheese making process. Additionally, calibration solutions should be included in the toolkit to ensure that measurements remain accurate over time. Maintaining an optimal pH during cheese making not only guarantees the right texture but also helps in enhancing the flavor, ensuring that the home cheese maker produces a delightful product similar to that of artisanal cheesemakers.

Moreover, including a digital thermometer in the set of tools is crucial, as temperature and pH are interconnected in the cheese making process. The right temperature can influence how the cultures and enzymes behave, ultimately affecting the acidity. A comprehensive report from the International Dairy Federation emphasizes that understanding these relationships can help home cheese makers achieve consistency and quality in their cheese production. Thus, investing in tools for measuring pH levels is not just an added advantage; it is a necessity for anyone looking to create authentic cheese at home.

pH Levels of Different Cheese Types

Role of Cheese Molds and Presses in Texture Development

The texture of cheese is a critical aspect that profoundly influences its taste and overall enjoyment. Among the essential equipment for cheese making, cheese molds and presses play a pivotal role in developing this texture. Cheese molds shape the curds into specific forms while ensuring proper drainage of whey, which is vital for achieving the desired consistency.

The choice of mold, whether it is a soft cheese mold for delicate varieties or a harder mold for aged cheeses, can significantly alter the final product's mouthfeel.

In conjunction with molds, cheese presses contribute further to texture development by applying controlled pressure to the curds. This pressure helps expel additional whey and compacts the curds, facilitating a firmer and more cohesive structure. The pressing process can vary in intensity and duration, depending on the type of cheese being produced.

This step is crucial as it not only aids in moisture loss but also influences the cheese's aging potential and flavor profile. By understanding the roles of molds and presses, home cheese makers can better control their crafting process, resulting in a wide range of textures and styles in their homemade cheese.

Hygiene Practices and Equipment for Safe Cheese Handling

Maintaining hygiene during cheese making and handling is critical to ensuring the safety and quality of the final product. According to the Centers for Disease Control and Prevention (CDC), practice of proper hygiene can significantly reduce the risk of foodborne illnesses associated with dairy products. To this end, cheese makers should prioritize the cleanliness of their workspace and equipment. Regularly sterilizing tools and using food-safe sanitizers are essential practices. A study published by the Journal of Dairy Science highlights that bacteria levels can increase by as much as 20% if proper sanitation practices are neglected.

In addition to cleanliness, cheese makers should use equipment designed to facilitate safe cheese handling. Essential tools include thermometers for monitoring milk temperatures, pH meters for acidity checks, and specialized molds that promote even fermentation. The Global Journal of Dairy Technology notes that using high-quality, non-porous equipment can minimize contamination risks. Moreover, adopting practices like wearing gloves and hairnets can further reduce the likelihood of introducing harmful pathogens into the cheese-making process. By implementing these hygiene practices, home cheese makers can ensure not only the safety but also the quality of their artisanal creations.

Related Posts

-

How to Choose the Best Fruit Machinery for Your Business Needs

-

Why Choosing the Right Creamery Equipment is Essential for Your Dairy Business

-

Top 10 Essential Food Machinery Equipment for Your Business Success

-

How to Choose the Best Fruit Machinery for Your Business Needs

-

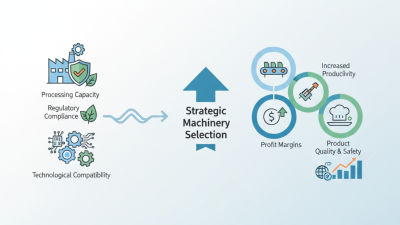

How to Choose the Right Food Industry Machinery for Your Business Needs

-

10 Essential Tips for Choosing the Right Dairy Machinery for Your Farm

Sell your machinery

Call us now on

+44 (0)1373 831 373

Sign up to our newsletter

Monkspool House,

The Stable,

Woolverton, Somerset.

BA2 7QT

United Kingdom