How to Choose the Right Food Industry Machinery for Your Business Needs

In the ever-evolving landscape of the food industry, selecting the right food industry machinery is pivotal for businesses aiming to enhance efficiency and maintain high product quality. According to a report by MarketsandMarkets, the global food processing equipment market is projected to reach USD 82.4 billion by 2025, growing at a CAGR of 6.3% from 2020 to 2025. This trend underscores the increasing reliance on advanced machinery to meet consumer demands and regulatory standards.

Choosing the appropriate machinery not only affects production volume but also impacts operational costs, food safety, and sustainability practices. In fact, a survey conducted by the Food Machinery Association indicated that 65% of food manufacturers prioritize automation and technological advancements when investing in new equipment. These choices can lead to significant improvements in productivity and profit margins, while also addressing the growing concerns of sustainable production.

As businesses navigate this critical phase, understanding the key factors influencing machinery selection—such as processing capacity, regulatory compliance, and technological compatibility—becomes essential. Adopting a strategic approach to sourcing food industry machinery tailored to specific operational needs can determine a company’s ability to thrive in a competitive market while meeting the expectations of a discerning customer base.

Understanding Your Business Requirements for Food Machinery Selection

When choosing the right food industry machinery for your business, it's essential to first understand your specific business requirements. This involves evaluating the scale of your operations, the types of products you intend to produce, and the production volume you anticipate. For instance, a small bakery may need different equipment compared to a large-scale food processing plant. Analyzing your production process will help identify whether you need mixers, conveyors, packaging machines, or specialized machinery tailored to your products.

Additionally, consider the versatility and efficiency of the machinery. As your business grows, you may want equipment that can adapt to various food items or changes in production demands. It’s also crucial to think about ease of maintenance and the availability of spare parts, as these factors will impact your operational efficiency and downtime. Furthermore, assessing your budget is vital; you should find a balance between quality and cost-effectiveness without compromising on safety and compliance with food industry regulations. By clearly defining your needs and priorities, you can make an informed decision that aligns with your business goals.

Food Industry Machinery Selection Based on Business Needs

Evaluating Production Capacity and Efficiency in Food Machinery Choices

When selecting food industry machinery, evaluating production capacity and efficiency is crucial for both short-term operation and long-term sustainability. By 2023, the global food processing machinery market is projected to grow significantly, with a compound annual growth rate (CAGR) of over 6%, indicating an increasing emphasis on efficient production methods. When assessing machinery options, businesses should focus on throughput capabilities and energy consumption metrics to ensure optimal operational performance.

Tips: Start by calculating your current and anticipated production volumes. A machinery solution that can easily scale with your growth will save costs in the long run. Furthermore, consider the energy efficiency ratings of each option. Equipment that uses less energy can reduce operational costs significantly — some reports indicate that upgrading to energy-efficient machinery can cut energy expenses by up to 30%.

Workforce efficiency is also influenced by machinery capabilities. Advanced technology, such as automation in food processing, can improve not only the speed of production but also the precision, decreasing waste and maximizing output. Data from industry experts suggest that integrating automation can lead to productivity increases of up to 25%. Always review vendor specifications and consult with experts to align machinery choices with your production objectives.

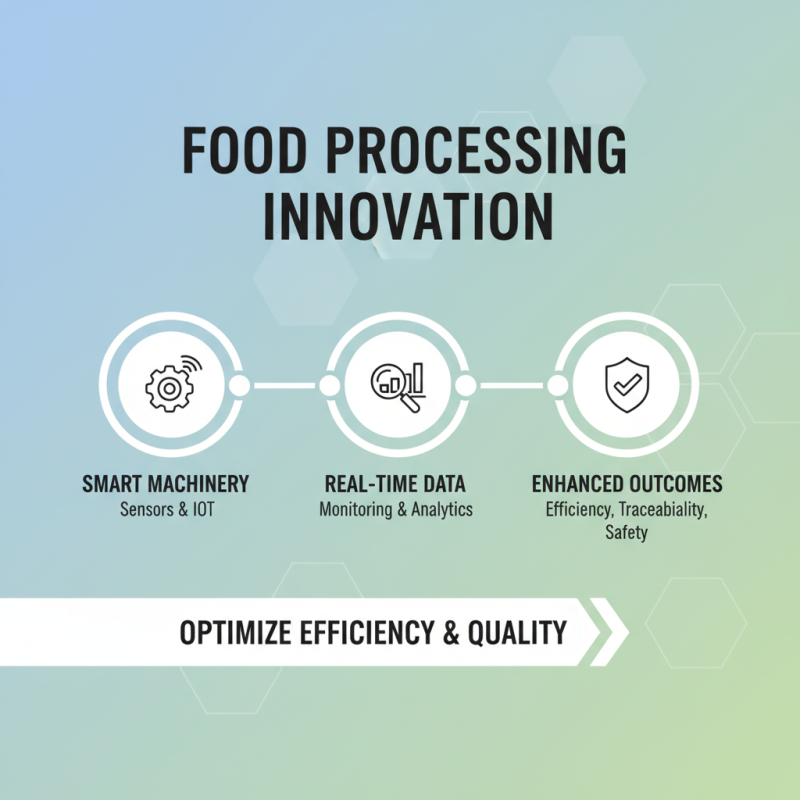

Assessing Technology and Innovation Trends in Food Processing Equipment

In the rapidly evolving landscape of the food processing industry, staying abreast of technology and innovation trends is essential for any business looking to optimize efficiency and quality. Recent advancements have transformed machinery into smart systems equipped with sensors and IoT connectivity, enabling real-time monitoring and data analytics. These innovations not only enhance productivity but also facilitate better traceability and compliance with safety standards. As a result, choosing machinery that integrates seamlessly with existing processes can significantly boost operational performance.

**Tips:** Consider investing in automation technologies that can streamline repetitive tasks. This will not only reduce the risk of human error but will also free up your workforce to focus on more critical activities. Additionally, staying informed about emerging technologies, such as AI and machine learning, can help identify areas for further improvement and innovation within your production processes.

Moreover, evaluating equipment that boasts flexibility and scalability allows your business to adapt to changing market demands without incurring hefty costs for new machinery. Look for versatile solutions that can handle a variety of products or packaging styles, which will enable your enterprise to pivot more easily as consumer preferences shift.

**Tips:** Regularly assess market trends and gather feedback from your team to identify machinery needs aligned with your business strategy. Keeping an open line of communication with suppliers can also provide valuable insights into upcoming innovations and technologies that could benefit your operations.

Budget Considerations: Cost Analysis of Food Industry Machinery Options

When selecting machinery for the food industry, one of the crucial elements to consider is the budget. A comprehensive cost analysis can significantly influence your purchasing decisions. According to a recent report from **Industry Week**, food processing machinery can range from tens of thousands to millions of dollars, depending on the complexity and capacity of the equipment. It is essential to evaluate not just the initial investment but also the total cost of ownership, which includes maintenance, energy consumption, and the potential for production downtime.

For instance, a study by the **Food Processing Association** suggests that maintenance costs can account for up to 20% of the total operating budget for manufacturing facilities. With machinery that requires frequent repairs or replacements, the long-term financial impact can be substantial. Therefore, businesses should conduct a thorough cost-benefit analysis, weighing factors such as purchase price against the expected lifespan and efficiency gains offered by various machinery options.

Moreover, understanding the scalability of the equipment is vital. As the market demand fluctuates, businesses may find themselves needing to upscale or downscale production capacity. Reports from **Market Research Future** indicate that modular machinery designs are on the rise, allowing for flexibility at a reduced cost. Investing in scalable options can help avoid significant expenditures when expanding production capabilities, making a careful budget analysis even more critical in the selection process.

Compliance and Safety Standards for Food Processing Equipment Selection

When selecting food processing equipment, compliance with safety standards is paramount to ensure both product quality and consumer safety. According to a report by the Food Safety and Inspection Service (FSIS), adherence to regulations such as the FDA’s Hazard Analysis and Critical Control Points (HACCP) principles is critical in preventing foodborne illnesses. Machinery must be designed to meet these stringent guidelines, which dictate proper sanitation procedures and facilitate efficient cleaning processes. Equipment that is compliant not only minimizes risks but also enhances operational efficiency by avoiding downtimes associated with safety violations.

Additionally, the International Organization for Standardization (ISO) has set the ISO 22000 standard, which outlines the requirements for a food safety management system. This includes ensuring that the machinery used in food processing is regularly inspected and maintained to meet hygiene and safety standards. Investing in equipment that complies with ISO guidelines can significantly reduce the likelihood of contamination, as highlighted in a study by the International Journal of Food Microbiology, which suggests that companies that adhere to such standards experience a 30% decrease in food safety issues. Selecting machinery that aligns with compliance and safety standards not only fulfills legal obligations but also builds consumer trust and enhances brand reputation in a competitive market.

How to Choose the Right Food Industry Machinery for Your Business Needs - Compliance and Safety Standards for Food Processing Equipment Selection

| Machinery Type | Key Compliance Standards | Safety Features | Maintenance Requirements | Typical Applications |

|---|---|---|---|---|

| Mixers | FDA, NSF | Emergency stop, safety guards | Regular cleaning, lubrication checks | Baking, sauces, dairy |

| Packagers | HACCP, ISO 22000 | Sealing mechanisms, overload protection | Calibration, part replacements | Snacks, beverages, frozen foods |

| Conveyors | OSHA, CE Mark | Emergency stop buttons, guards | Routine inspections, lubrication | Material handling, packaging |

| Pasteurizers | FDA, 3-A Sanitary Standards | Temperature control, monitoring systems | Cleaning validation, regular inspections | Juice, dairy, sauces |

Sell your machinery

Call us now on

+44 (0)1373 831 373

Sign up to our newsletter

Monkspool House,

The Stable,

Woolverton, Somerset.

BA2 7QT

United Kingdom