What is Creamery Equipment and Its Importance in Ice Cream Production

Ice cream production is an intricate process that requires specialized machinery. The role of creamery equipment cannot be overstated. It encompasses a variety of tools, each designed for specific tasks. From pasteurization to freezing, the equipment ensures quality and consistency.

Without proper creamery equipment, production can suffer. For instance, inadequate mixing could lead to uneven flavors. This is a frequent challenge small producers face. They may overlook the importance of investing in high-quality machines. As a result, the final product may lack the desired texture or taste.

Moreover, maintaining this equipment is crucial. Regular checks can prevent costly breakdowns and downtime. Sometimes, overlooking minor repairs can snowball into larger issues. Therefore, understanding the significance of creamery equipment is essential for anyone in the ice cream industry. Emphasizing maintenance and appropriate selection can deeply influence production quality. The path to perfect ice cream begins with the right tools.

What is Creamery Equipment?

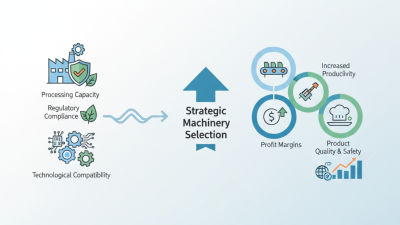

Creamery equipment plays a crucial role in ice cream production. It encompasses various machines and tools that ensure the quality and efficiency of the process. From pasteurizers to freezers, each piece of equipment serves a specific purpose. According to industry reports, more than 70% of ice cream manufacturers emphasize modernizing their equipment to boost productivity.

For example, pasteurizers heat the mixture to eliminate harmful bacteria. This process is essential for safety. Furthermore, continuous freezers churn the ice cream mixture while freezing it. This creates a smooth texture. However, upgrading equipment can be costly. Many small producers may struggle with the expense. They often operate with outdated machinery, affecting product consistency.

Maintenance of this equipment is also critical. Regular checks can prevent breakdowns and ensure steady production. A survey indicated that over 50% of production delays stem from equipment failure. Some producers may overlook this, leading to losses. Investing in reliable creamery equipment can ultimately enhance quality control and product reliability in a competitive market.

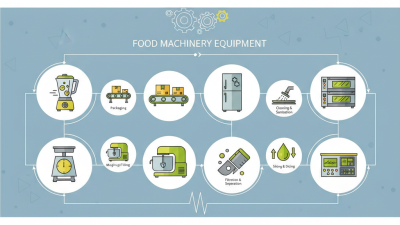

Types of Creamery Equipment Used in Ice Cream Production

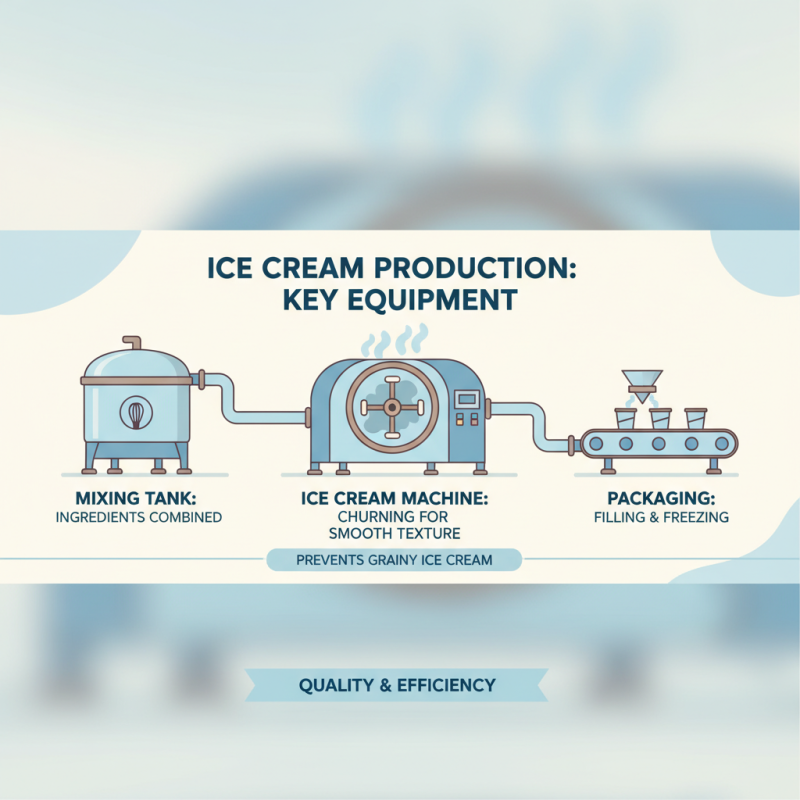

Creamery equipment plays a vital role in ice cream production by ensuring quality and efficiency. Various types of equipment exist, each serving a specific purpose. Ice cream machines are at the heart of the process. They mix ingredients and churn the mixture to create a smooth texture. This step is crucial; a poorly functioning machine can lead to grainy ice cream.

Another important type is the pasteurizer. It heats the mixture to eliminate harmful bacteria. This machine must operate accurately to maintain the right temperature. Any inconsistency during pasteurization could compromise safety. Additionally, batch freezers play a critical role. They help freeze the ice cream mixture quickly. Rapid cooling improves flavor and texture.

Lastly, some manufacturers invest in quality control equipment. This includes tools for testing overrun and flavor profiles. While many focus on production speed, neglecting these checks can lead to inferior products. The need for balance in efficiency and quality cannot be overstated. Ice cream production relies on machinery that works well. However, occasional breakdowns or mistakes remind producers about the importance of maintenance and constant improvement.

Role of Creamery Equipment in Ensuring Product Quality

Creamery equipment plays a vital role in ice cream production. It ensures the consistency and quality of the final product. Mixing tanks blend ingredients thoroughly, creating a uniform base. If the mixture is uneven, the texture and flavor can suffer. This is a common oversight in many production lines.

Freezers are crucial as well. They incorporate air into the mix, giving ice cream its light texture. Poor freezer performance can lead to ice crystals forming, making the ice cream grainy. Maintaining this equipment is essential yet often neglected. Cleaning procedures should be regular. Otherwise, flavors may become tainted.

Pasteurizers are designed to eliminate unwanted bacteria. They help achieve safety standards while preserving flavor. Inadequate pasteurization can lead to spoilage quickly. This underscores the importance of regular checks and balances in equipment. Investing time in these areas often reveals areas for improvement. Quality control should be ongoing, not just a checklist.

Maintenance and Safety Practices for Creamery Equipment

Maintaining creamery equipment is crucial for ice cream production. Regular maintenance can reduce unplanned breakdowns. Inspecting machines weekly helps catch issues early. Check for leaks and unusual noises during daily operations. Equipment that runs smoothly ensures efficient production.

Safety practices are equally important. Workers should wear proper protective gear while operating machines. This includes gloves, masks, and eyewear to prevent accidents. Proper training is essential. All staff should understand how to use equipment safely. It’s also vital to have emergency procedures in place.

Failure to adhere to these practices can lead to serious accidents. Equipment that isn’t regularly serviced can break down unexpectedly. Developing a maintenance schedule is a proactive step. The investment in time can prevent larger costs down the road. Reflecting on past mistakes can lead to better practices in the future.

Future Trends in Creamery Equipment for the Ice Cream Industry

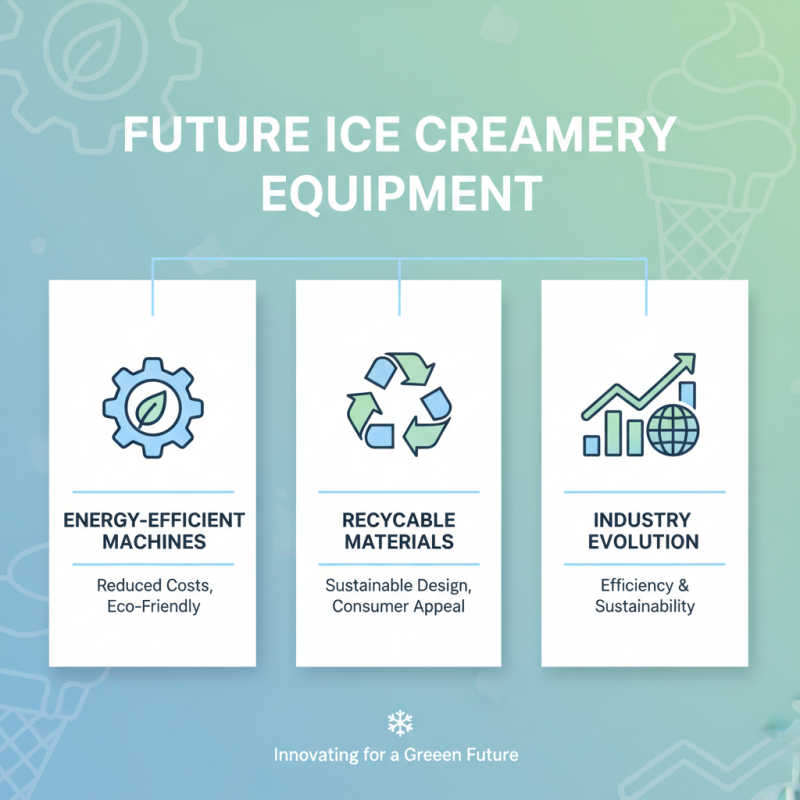

The ice cream industry is evolving. Future trends in creamery equipment focus on efficiency and sustainability. Manufacturers are now turning to energy-efficient machines. These innovations can reduce costs significantly and appeal to eco-conscious consumers. The use of recyclable materials in equipment design is also gaining traction. This shift aligns with the growing demand for environmentally friendly practices in food production.

Automation is another key trend. Smart equipment can streamline processes. It improves consistency and reduces labor costs. However, businesses must weigh their investments carefully. Not every automated solution fits all production scales. Cloud technology allows for better monitoring of operations. This accessibility helps in maintaining quality control throughout the production phases.

Tip: Consider investing in equipment that offers scalability. This ensures you can adjust your production as demand changes. Regular training for staff on new technologies is essential. Keep everyone informed about best practices. Emphasizing flexibility in operations can lead to better product outcomes. Experimentation and adaptation will be crucial for future growth.

Related Posts

-

Why Choosing the Right Creamery Equipment is Essential for Your Dairy Business

-

10 Essential Tips for Choosing the Right Dairy Machinery for Your Farm

-

How to Choose the Best Fruit Machinery for Your Business Needs

-

How to Choose the Best Fruit Machinery for Your Business Needs

-

Top 10 Essential Food Machinery Equipment for Your Business Success

-

How to Choose the Right Food Industry Machinery for Your Business Needs

Sell your machinery

Call us now on

+44 (0)1373 831 373

Sign up to our newsletter

Monkspool House,

The Stable,

Woolverton, Somerset.

BA2 7QT

United Kingdom