How to Produce Packaging Machinery for Efficient Manufacturing Processes?

In today's competitive landscape, the need to produce packaging machinery efficiently is more pressing than ever. According to a recent report by Smithers Pira, the global packaging machinery market is projected to reach $63 billion by 2024. This signifies a robust demand for innovative solutions. However, achieving efficiency in production processes remains a significant challenge for many manufacturers.

Expert opinions emphasize the importance of optimizing machinery production. Dr. Emily Carter, a leading expert in industrial automation, states, "To produce packaging machinery that meets modern demands, manufacturers must embrace smart technologies." These technologies not only enhance production speed but also improve flexibility in meeting customer needs. Yet, integrating such technologies requires careful planning and investment.

Many manufacturers struggle with outdated systems, leading to inefficiencies. Improving the design process is crucial. Continuous refinement of production techniques is vital. Companies must assess their machinery capabilities regularly. Without proactive strategies, they risk falling behind in a rapidly evolving market. The path to success in producing packaging machinery hinges on a commitment to innovation and adaptability.

Understanding the Importance of Packaging Machinery in Manufacturing

Packaging machinery plays a crucial role in manufacturing processes. It streamlines operations and ensures consistency. Efficient packaging reduces waste, which is essential for sustainable practices. When machinery malfunctions, delays can occur, leading to higher costs. A well-functioning system keeps the production line moving smoothly.

Understanding the importance of packaging machinery also means recognizing its variety. Different products require different packing solutions. Some machinery can handle diverse sizes and shapes, but not all of them can. This lack of versatility can limit production efficiency. Regular maintenance is vital to address wear and tear. Without it, even the best machines can become liabilities.

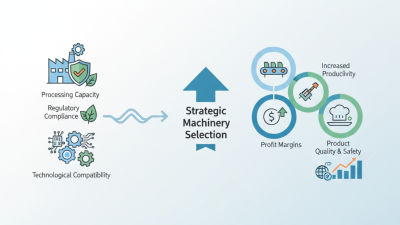

Investing in the right equipment is necessary but challenging. Companies must balance cost and function. Some may opt for cheaper models and regret it later. These struggles highlight the need for careful planning. Manufacturers should evaluate their specific needs before making a purchase. Reflecting on past experiences can guide future decisions.

Key Components of Effective Packaging Machinery Design

Efficient packaging machinery is crucial in modern manufacturing processes. Key components in design can make or break your production line. For instance, automation has dramatically changed the landscape. According to a report by the International Society for Automation, over 70% of high-performing manufacturers utilize some degree of automation in their packaging lines.

Design of packaging machinery should focus on flexibility. This allows quick changes between different products. A rigid design can limit productivity. Engineers often need to rethink layouts and interfaces to enhance adaptability. Data from Packaging Strategies highlights that 65% of companies report longer downtime due to inflexible machinery setups.

Another important aspect is user-friendliness. Machines that are difficult to operate result in poor performance. Around 40% of workers cite inadequate training on new machines as a major hindrance. Regular feedback from operators helps in identifying issues. Failing to adjust based on this input could lead to inefficiencies. Each design element should be evaluated, considering real-world applications and potential employee insight.

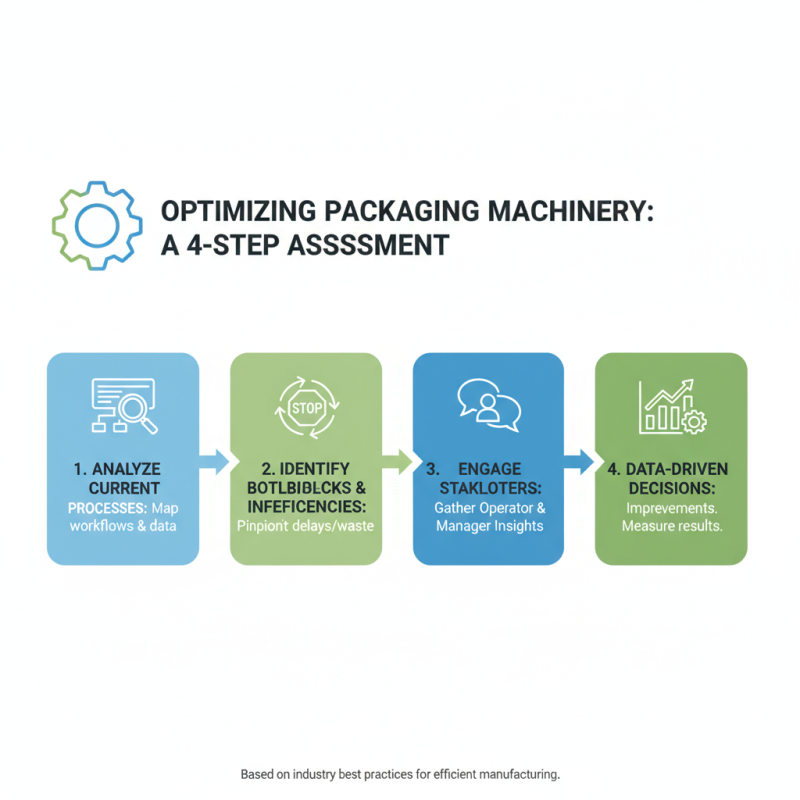

Steps for Assessing Manufacturing Needs and Requirements

Assessing manufacturing needs is crucial in producing efficient packaging machinery. Begin by analyzing current processes. Identify bottlenecks and inefficiencies. Engage with operators and managers to gather insights. Their feedback is invaluable. Data-driven decisions yield better results.

Next, focus on the types of products being packaged. Understand the dimensions, weights, and materials involved. This information shapes the machinery design. Look for customization opportunities. However, not every solution will meet your expectations. Some may require adjustments mid-production.

Another area of reflection involves budget constraints. Balancing cost with quality is often challenging. Invest in reliable machinery that meets future needs. Avoid cutting corners just to save money. Additionally, remember that technology evolves. Staying updated is crucial for long-term efficiency. It’s a continuous learning process, and adjustments will be necessary as your requirements change.

Best Practices for Testing and Quality Assurance in Machinery Production

Testing and quality assurance are vital in machinery production. A thorough testing phase can catch flaws early. Regular inspections should be part of the routine. For example, a machine might fail due to an unnoticed design error. These errors can lead to costly delays and safety risks.

To ensure reliability, staff training is crucial. Operators should understand how to test machinery effectively. Using checklists can help maintain consistency. Sometimes, even minor components can cause significant issues. Testing small parts, like sensors, is equally important.

Quality assurance should be an ongoing process. Gathering feedback from operators is essential. They can provide insights that engineers might overlook. Continuous improvement is necessary. Reflecting on past mistakes can lead to better practices. Embracing a culture of quality ensures that each machine meets high standards.

Future Trends in Packaging Machinery for Enhanced Efficiency

The future of packaging machinery is driven by the demand for efficiency. Automation is a key trend. Machines are now designed to work seamlessly with minimal oversight. This results in faster production times and less human error. Companies are integrating AI to optimize processes. Smart sensors monitor performance, adjusting operations in real-time.

Sustainability can't be ignored. Many manufacturers are investing in eco-friendly materials. This shift helps reduce waste and lowers production costs. However, the transition is not without challenges. Finding the right materials can be complex. Ensuring efficiency while being sustainable requires careful planning.

Customization is becoming increasingly important. Tailored solutions meet specific needs. However, developing these customized machines can delay production schedules. Balancing flexibility with efficiency remains a work in progress. Businesses must innovate while keeping an eye on costs and timelines. The road ahead is full of potential, but obstacles must be addressed to achieve true efficiency.

Related Posts

-

How to Choose the Best Fruit Machinery for Your Business Needs

-

Top 10 Essential Food Machinery Equipment for Your Business Success

-

Why Choosing the Right Creamery Equipment is Essential for Your Dairy Business

-

How to Choose the Right Food Industry Machinery for Your Business Needs

-

10 Essential Tips for Choosing the Right Dairy Machinery for Your Farm

-

10 Best Cheese Equipment You Need for Perfect Cheese Making at Home

Sell your machinery

Call us now on

+44 (0)1373 831 373

Sign up to our newsletter

Monkspool House,

The Stable,

Woolverton, Somerset.

BA2 7QT

United Kingdom