Top 10 Food Machinery Equipment You Should Know About?

In the dynamic world of food production, food machinery equipment plays a crucial role. According to Mark Thompson, an expert in the food technology field, "Choosing the right equipment can enhance productivity and ensure food safety." Understanding the essential machines in this industry can significantly impact operational success.

The top 10 food machinery equipment includes mixers, ovens, and conveyor belts. Each piece serves a specific function, streamlined for efficiency. However, it's vital to consider the flaws in these systems. Machinery can malfunction, leading to costly downtimes and safety hazards. Regular maintenance is often overlooked, yet it is critical for optimal performance.

Moreover, not all equipment suits every operation. Small businesses may struggle with high-capacity machines that are too complex or expensive. Balancing needs and resources requires thoughtful reflection. By evaluating the essentials, operators can better navigate the complexities of food machinery equipment. The right choices shape the future of food production.

Essential Overview of Food Machinery Equipment in the Industry

The food machinery equipment market is vast and ever-evolving. According to a recent industry report, the global food processing equipment market was valued at over $60 billion in 2022, and it is expected to grow at a CAGR of 5.4% through 2030. This growth reflects the increasing demand for efficient food processing solutions, driven by population growth and changing consumer preferences.

In the industry, essential machinery ranges from mixers and slicers to conveyors. Each machine plays a critical role in enhancing productivity and ensuring food safety. For instance, pasteurizers help in extending the shelf life of dairy products. However, many businesses still rely on outdated technology, leading to inefficiencies. The high cost of modern equipment can deter small-scale producers from upgrading. This gap signals a pressing need for accessible training and resources.

Maintaining this equipment is crucial but often neglected. Regular servicing can prevent equipment failure, which can lead to production delays. In fact, reports indicate that unscheduled downtime can cost manufacturers thousands of dollars. Taking proactive steps to address maintenance can significantly impact operational efficiency and profitability.

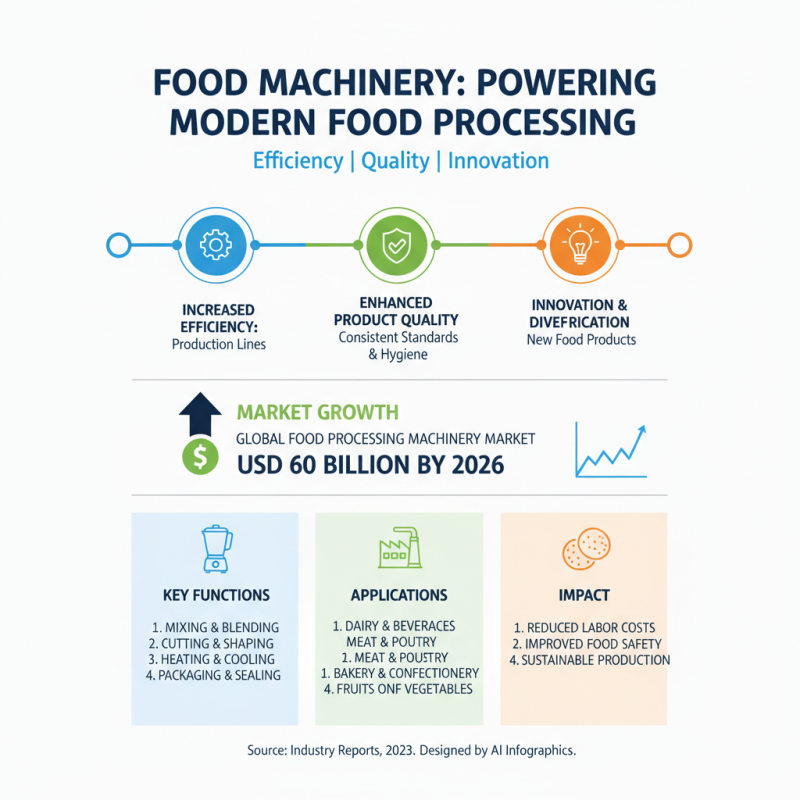

Key Functions and Applications of Food Machinery

Food machinery plays a crucial role in modern food processing. It enhances efficiency and ensures product quality. According to industry reports, the global food processing machinery market is projected to reach USD 60 billion by 2026. This surge underscores the importance of understanding key functions and applications of these machines.

Mixers and blenders stand out for their versatility. They can blend, whip, and mix diverse food items. These machines improve uniformity in products but can lead to over-mixing, which impacts texture. Another critical machine is the food slicer. It ensures consistent cut sizes, which is vital for cooking and presentation. Over-reliance on automation can result in losing traditional cutting skills among workers.

Packaging equipment is essential in extending shelf life. It not only seals but also protects food from contamination. However, improper packaging can lead to spoilage. Data suggests that nearly 20% of perishables get wasted due to inadequate packaging. Understanding these machines’ roles allows better planning and investment in food production lines. It’s not just about machines; it’s about how they integrate into existing processes.

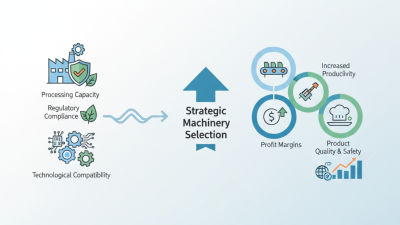

Top Factors to Consider When Selecting Food Machinery

Selecting the right food machinery equipment is crucial for efficient production. When choosing, consider the machinery’s capacity. A report from the Food Processing Industry states that machines with higher throughput can improve overall productivity by up to 30%. Size matters too. Ensure the equipment fits your production space and workflow.

Another key factor is energy efficiency. Equipment that consumes less energy can decrease operational costs. According to the same report, energy-efficient machines can save companies up to 20% on their annual energy bills. Maintenance requirements are also important. Some machines need more regular service, which can create unplanned downtime.

Tips: Always check the warranty details. A good warranty ensures you're covered against defects. Consult with other companies in the industry for insights. Trade shows are excellent for hands-on evaluations. Don’t overlook software compatibility. Some machines require advanced software for optimal functioning. Evaluate your long-term needs, as trends can shift rapidly in the food sector. Choose equipment that can adapt to changes in production demand.

Innovative Technologies in Food Processing Equipment

In the rapidly evolving food industry, innovative technologies play a crucial role in improving food processing equipment. These advancements enhance efficiency, safety, and quality. For example, automated systems reduce human error and increase precision. Machines equipped with cutting-edge sensors can monitor temperature and humidity levels in real-time. This ensures optimal conditions for food preservation.

Another significant trend is the integration of artificial intelligence. AI-driven machines can analyze data and predict potential issues. This proactive approach reduces downtime and enhances productivity. However, reliance on technology can create challenges. Not all operators are familiar with these systems, leading to a steep learning curve.

Moreover, sustainability is a growing concern. Many food processing sectors are embracing eco-friendly technologies. These machines reduce waste and energy consumption. Yet, the initial investment can be a barrier for smaller companies. Innovation is not without its hurdles. The industry must balance modernization and accessibility. Improvements must be continuous to meet the demands of an evolving market.

Future Trends in Food Machinery Advancements

The food machinery industry is evolving rapidly. Innovative technologies are reshaping how food is processed and packaged. According to a recent report from the Food Machinery Manufacturers Association, the global market is expected to reach $350 billion by 2025. Automation plays a crucial role in this growth. Sophisticated machines reduce labor costs and increase efficiency.

Emerging trends highlight the importance of sustainability. Many consumers demand eco-friendly practices. Equipment that minimizes waste and energy consumption is gaining popularity. Reports suggest that energy-efficient machinery can cut operational costs by 20%. However, some manufacturers struggle to keep up with these advancements. Not all facilities can afford to upgrade their equipment.

Digitalization also presents new opportunities. Smart machines equipped with IoT capabilities enable real-time monitoring. This technology helps manage production better. But, not every company is ready for such changes. Many still rely on outdated systems. As the industry moves forward, these issues need addressing. The future of food machinery may be bright, but hurdles remain.

Top 10 Food Machinery Equipment You Should Know About

| Equipment | Purpose | Latest Trend | Efficiency Improvement |

|---|---|---|---|

| Automatic Filling Machines | Fills containers with various products | Smart sensors for precision | Increased speed by 30% |

| Food Processors | Chops, mixes, and purees food | AI integration for recipe suggestions | Reduced preparation time by 25% |

| Industrial Ovens | Bakes and cooks food products | Energy-efficient designs | Lower energy consumption by 20% |

| Packaging Machines | Packages food products securely | Robotics for handling | Boosted output by 50% |

| Labeling Machines | Applies labels to packaging | Automated alignment technology | Accuracy rate improved to 99% |

| Sorting Equipment | Sorts food items by size and quality | Machine learning for enhanced sorting | Increased sorting speed by 40% |

| Mixer/Blenders | Mixes ingredients thoroughly | Variable speed controls | Reduction in clumping by 35% |

| Cooling Equipment | Chills food products efficiently | CFC-free refrigeration | Energy savings of 15% |

| Conveyors | Transport products within facility | Smart routing algorithms | Cut operating time by 20% |

| Extruders | Shapes and forms food products | 3D food printing capabilities | Production costs reduced by 15% |

Related Posts

-

How to Choose the Right Food Industry Machinery for Your Business Needs

-

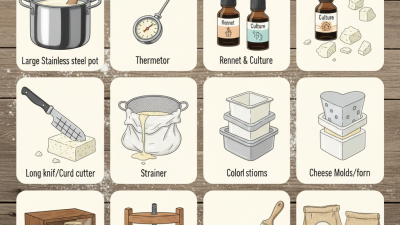

10 Best Cheese Equipment You Need for Perfect Cheese Making at Home

-

Why Is Creamery Equipment Essential for Successful Ice Cream Production?

-

How to Choose the Best Fruit Machinery for Your Business Needs

-

Why Choosing the Right Creamery Equipment is Essential for Your Dairy Business

-

Top Bakery Product Machinery Innovations for Modern Baking Success?

Sell your machinery

Call us now on

+44 (0)1373 831 373

Sign up to our newsletter

Monkspool House,

The Stable,

Woolverton, Somerset.

BA2 7QT

United Kingdom