Top Tips for Choosing the Best Dairy Machinery for Your Farm?

Choosing the right dairy machinery is crucial for any successful farm. As John Smith, a renowned dairy expert, once said, “Quality machinery leads to better milk production.” This statement highlights the importance of making informed choices.

When selecting dairy machinery, consider efficiency, durability, and maintenance needs. Modern equipment can greatly enhance productivity. However, the wrong choice can lead to wasted resources and increased costs. It’s not just about price; features must match your specific farm operations.

Additionally, think about the long-term implications of your decision. Investing in advanced dairy machinery might stretch your budget today, but it can pay off in efficiency tomorrow. Reflect on your farm’s unique needs before making a choice. Remember, the right equipment can transform your dairy operations but requires thoughtful consideration.

Understanding Dairy Machinery Types and Their Functions

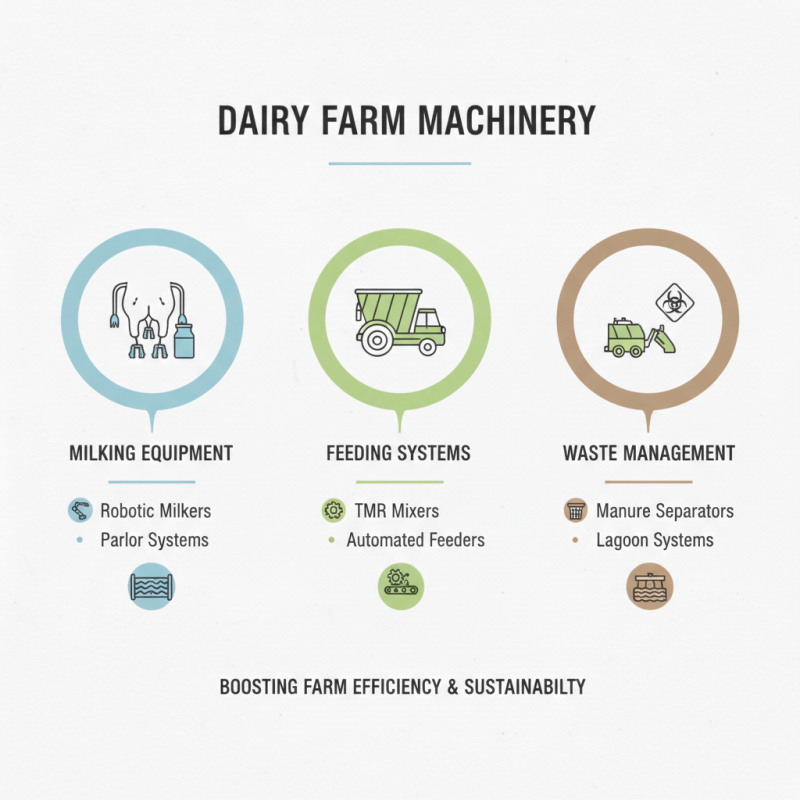

Dairy machinery plays a crucial role in modern farming. Understanding the types of machinery available is essential. There are several key categories: milking equipment, feeding systems, and waste management tools. Each type serves a specific function and can significantly impact farm efficiency.

Milking equipment, like machines and tanks, streamline the milking process. Reports show that automated milking systems can increase milk yield by up to 15%. This efficiency is vital for larger operations. Feeding systems, meanwhile, ensure cattle receive the right nutrients. Proper nutrition improves milk production and animal health.

Lastly, waste management machinery is often overlooked. Efficient waste handling can reduce environmental impact. According to industry studies, effective waste management can lower greenhouse gas emissions by 20%. However, not every farm invests in the latest technology. Many continue using outdated systems. This can lead to inefficiencies and missed opportunities for growth and sustainability. Understanding these machinery types helps farmers make better choices.

Assessing Your Farm's Specific Dairy Production Needs

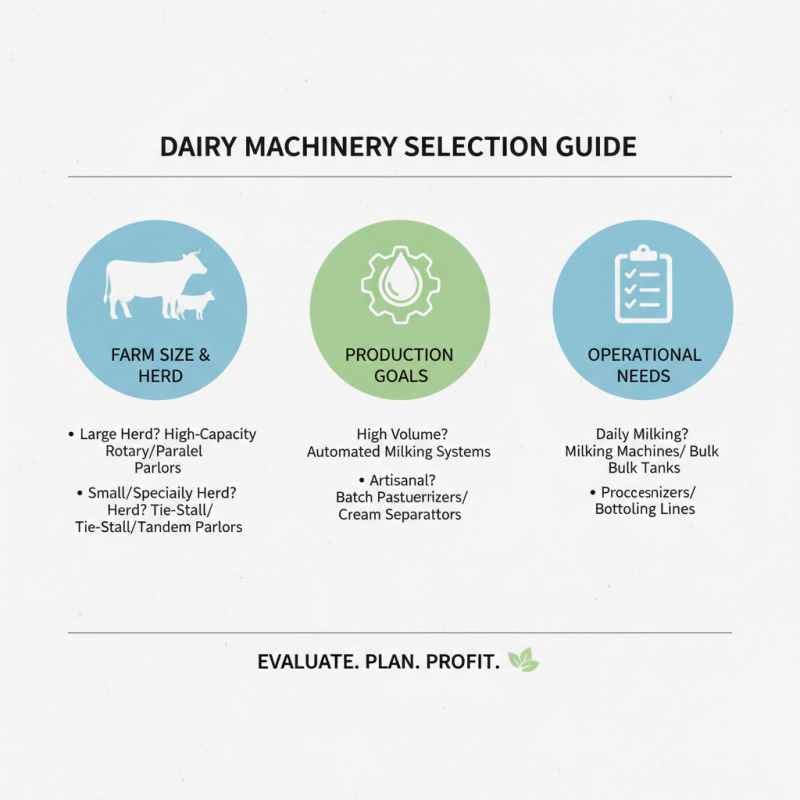

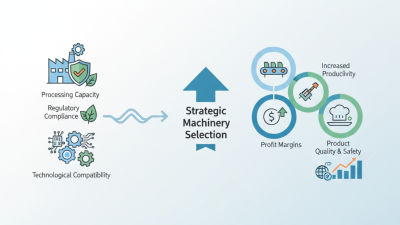

When selecting the right dairy machinery for your farm, it's crucial to evaluate your specific needs. Each farm has unique demands based on its size, herd composition, and production goals. Take stock of your daily operations. Are you milking a large number of cows? Or do you focus on a smaller, specialty herd? Understanding your production capacity can help identify the necessary equipment.

Consider the processes involved. From milking to storage, each step might require different machinery. For instance, if you aim for higher efficiency, an automated milking system could save time. On the other hand, you might prioritize a traditional method for better animal care. Analyze your priorities and budget. Machinery can be a significant investment.

Here’s a tip: consult with other farmers. They can share experiences about their equipment choices. It’s crucial to gather insights from those who face similar challenges. Additionally, attending industry exhibitions may open your eyes to new innovations. Reflect on what has worked well and what hasn't. This information can steer you toward the best machinery for your specific needs.

Key Features to Look for in Dairy Machinery

When selecting dairy machinery for your farm, focus on key features that enhance efficiency. Look for equipment that is user-friendly and has clear controls. Ease of operation is vital for smooth daily tasks. Consider machines that offer automatic settings, reducing manual work and potential errors.

Another important aspect is durability. The machinery should withstand various farm conditions. It is wise to choose equipment made from high-quality materials. Such machinery is an investment that pays off over time. Regular maintenance can extend the lifespan, but be prepared for occasional repairs.

Efficiency is crucial in dairy operations. Opt for machinery that minimizes energy consumption. This can lead to lower operational costs. Look for features that enable quick cleaning processes as well. A machine that is easy to clean saves time and promotes hygiene. Remember, the right machinery will streamline your work but may require adjustments initially. Experience will guide you in maximizing its potential.

Top Tips for Choosing the Best Dairy Machinery for Your Farm

Evaluating Budget and Cost-Effectiveness of Equipment

When evaluating the budget and cost-effectiveness of dairy machinery, consider both initial costs and long-term investments. A report by the International Dairy Federation highlights that efficient machinery can boost productivity by up to 20%. This statistic emphasizes the need for careful financial planning.

Tip: Look for equipment that offers a good return on investment. Assess how many years you expect to use the machinery. Calculate the total cost over its lifespan, including maintenance and energy consumption. For example, a milking system expected to last ten years might be more cost-effective than cheaper options.

Also, remember that the cheapest option is not always the best. You may face higher repair costs or more downtime with low-quality equipment. Research shows that higher-priced equipment often has better durability. However, ensuring the machinery fits your specific farm needs is vital. Be cautious about overspending on features you won’t use.

Tip: Prioritize essential functions over extra features. Create a detailed list of what you truly need versus what is nice to have. A focused approach prevents unnecessary expenses, helping you stay within your budget. The choice of machinery can significantly impact both your operations and overall financial health. Choose wisely.

Top Tips for Choosing the Best Dairy Machinery for Your Farm

| Machine Type | Initial Cost ($) | Maintenance Cost/Year ($) | Expected Lifespan (Years) | Efficiency Rating (%) | Cost-Effectiveness Score |

|---|---|---|---|---|---|

| Milking Machine | 15,000 | 1,200 | 10 | 90 | 7.5 |

| Feeding System | 20,000 | 1,500 | 12 | 85 | 6.5 |

| Cooling Tank | 25,000 | 800 | 15 | 92 | 9.2 |

| Manure Spreader | 18,000 | 1,000 | 8 | 80 | 6.0 |

| Vacuum Pump | 12,000 | 600 | 10 | 88 | 8.0 |

Researching and Comparing Different Dairy Machinery Brands

When selecting dairy machinery, researching various brands is crucial. Start by

identifying your farm’s specific needs. Consider the size of your operation and the

scale of production. It’s essential to choose machines that match your workflow. Unfortunately, some brands may not

be as reliable as they promise. Read reviews from other farmers. Their experiences can provide insights into

performance and durability.

Comparing brands is not just about the machinery itself. Check warranty terms

and customer service responsiveness. A good warranty can save you money in the long run. Additionally, consider

the availability of spare parts. If a machine

breaks down, will you be able to fix it quickly? It's frustrating when essential components are hard to find.

When visiting dealer shows or expos, take notes. Note the features that matter most to you. Be mindful of flashy

marketing versus real functionality. Sometimes, the simplest machines perform the best. Trust your instincts but

also remain critical. Keep an open mind, but do not rush into a decision.

Related Posts

-

How to Produce Packaging Machinery for Efficient Manufacturing Processes?

-

10 Essential Tips for Choosing the Right Dairy Machinery for Your Farm

-

10 Best Cheese Equipment You Need for Perfect Cheese Making at Home

-

How to Choose the Right Food Industry Machinery for Your Business Needs

-

Why Is Creamery Equipment Essential for Successful Ice Cream Production?

-

Why Choosing the Right Creamery Equipment is Essential for Your Dairy Business

Sell your machinery

Call us now on

+44 (0)1373 831 373

Sign up to our newsletter

Monkspool House,

The Stable,

Woolverton, Somerset.

BA2 7QT

United Kingdom